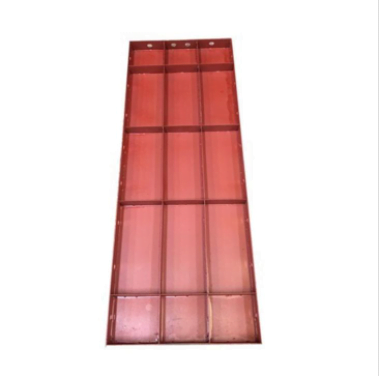

Steel Shuttering Plate

sConcrete Steel Shuttering Plates application:

- Building wall, beam, ceiling, staircase.

- Tower modular.

- Bridge modular.

- Tunnel shutters

- Special shape construction walls.

- Dam.

- Foundation of constructure Concrete

Advantages of Steel Shuttering Plates for Construction Projects

Steel shuttering plates are an essential component in the construction industry, providing sturdy and reliable support during the concrete pouring process. These plates offer numerous advantages over traditional materials, such as wood or plywood. In this article, we will explore the key benefits of using steel shuttering plates, highlighting their durability, cost-effectiveness, and eco-friendliness. By understanding these advantages, you can make an informed decision when choosing the right shuttering material for your construction project.

-

Superior Durability:

One of the primary advantages of steel shuttering plates is their exceptional durability. Unlike wooden or plywood shuttering, steel plates are resistant to warping, bending, and rotting. This durability ensures that the plates maintain their structural integrity, even under heavy loads and adverse weather conditions. Steel shuttering plates are also resistant to termites, mold, and other common issues associated with traditional materials. By opting for steel plates, you can enhance the lifespan of your shuttering system, minimizing the need for frequent replacements and repairs.

-

Increased Efficiency:

Steel shuttering plates are designed to streamline the construction process, improving efficiency on the job site. These plates are lightweight yet robust, allowing for easy handling and quick installation. Due to their standardized sizes and interlocking mechanisms, steel plates can be easily assembled and dismantled, reducing construction time significantly. The ease of use and quick setup make steel shuttering plates an ideal choice for projects with tight schedules or those requiring repetitive concrete pouring.

-

Cost-effectiveness:

While steel shuttering plates may have a higher upfront cost compared to wooden or plywood alternatives, they offer long-term cost-effectiveness. Steel plates have a longer lifespan, minimizing the need for replacement and maintenance. Their durability also ensures fewer instances of damage during handling and storage, reducing overall project costs. Additionally, steel plates can be reused multiple times, making them a sustainable and economical choice in the long run.

-

Versatility:

Steel shuttering plates are highly versatile, making them suitable for a wide range of construction projects. They come in various sizes and configurations, allowing for customization based on project requirements. Steel plates can be easily adjusted to create different formwork shapes and sizes, enabling flexibility in design. Their adaptability makes them suitable for constructing walls, columns, beams, and other structural elements. By choosing steel shuttering plates, you can achieve precise and accurate concrete formwork, ensuring a high-quality finished product.

-

Environmentally Friendly:

In an era of increasing environmental awareness, steel shuttering plates offer a sustainable alternative to traditional materials. Steel is a recyclable material, which means that the plates can be reused or repurposed at the end of their lifespan. This reduces waste generation and minimizes the environmental impact of construction projects. Additionally, steel shuttering plates do not contribute to deforestation, unlike wooden alternatives, making them an eco-friendly choice for builders committed to sustainable practices.

Steel shuttering plates provide significant advantages over conventional materials, enhancing construction efficiency, durability, and cost-effectiveness. Their superior strength, adaptability, and sustainability make them an excellent choice for modern construction projects. By opting for steel plates, you can ensure a reliable and efficient shuttering system that contributes to the success of your construction endeavors. Embrace the advantages of steel shuttering plates and witness the positive impact on your project’s quality, timeline, and budget.

- Steel Shuttering Plate Product Details

Concrete Steel Shuttering Plates description:

1. Steel shuttering is a kind of modular table formwork for building concrete construction.

2. The steel shuttering plates are reinforced by steel ribs so that it can bear high loading.

3. This concrete shuttering is perforated, you can use srew or u clip to fix them together.

Specification

| Item | Common Size | |||||||

| Length available | MM | 450 | 000 | 750 | 900 | 1200 | 1500 | 1800 |

| Feet | 1.5′ | 2′ | 2.5′ | 3′ | 4′ | 5′ | 6′ | |

| Width available | MM | 150 | 200 | 250 | 300 | 400 | 500 | 600 |

| Inch | 6” | 8” | 10” | 12” | 16” | 20” | 24” | |

Picture of Flat Formwork

Application

Steel Shuttering Plate

How to Apply the Steel Shuttering Plates ?

Steel shuttering plates are versatile and easy to use, making them a preferred choice for construction projects. Whether you are constructing walls, columns, beams, or other structural elements, the following step-by-step guide will help you effectively apply steel shuttering plates:

Step 1:

Prepare the Construction Site Ensure that the construction site is properly prepared before installing the steel shuttering plates. Clear the area of any debris, level the ground, and create a stable foundation for the plates. It’s important to have a solid and even surface to ensure the stability and accuracy of the formwork.

Step 2:

Determine the Required Plate Sizes Assess the dimensions and specifications of the concrete structure you are constructing. Based on this information, determine the appropriate size and quantity of steel shuttering plates needed. Steel plates are available in various standard sizes, so choose the ones that best fit your project requirements.

Step 3:

Clean and Inspect the Plates Before using the steel shuttering plates, thoroughly clean them to remove any dirt, grease, or debris that may affect their performance. Inspect each plate for any signs of damage or defects. It is important to ensure that the plates are in good condition and free from any structural issues.

Step 4:

Assemble the Plates Start by positioning the first steel shuttering plate in the desired location. Align it properly and secure it to the ground or supporting structure using suitable fasteners, such as clamps or bolts. Ensure that the plate is level and securely fixed to prevent any movement during the concrete pouring process.

Step 5:

Interlock the Plates Once the first plate is secured, proceed to interlock the subsequent plates. Steel shuttering plates are designed with interlocking mechanisms that allow them to connect seamlessly. Slide the second plate into the grooves or slots of the first plate and ensure a tight fit. Repeat this process for each additional plate until the desired formwork shape is achieved.

Step 6:

Reinforce the Joints To enhance the stability and strength of the formwork, reinforce the joints between the steel shuttering plates. This can be done by using suitable reinforcement materials such as steel bars, connectors, or clamps. Reinforcing the joints helps to prevent any gaps or misalignment, ensuring a uniform and secure formwork structure.

Step 7:

Check Alignment and Leveling Regularly check the alignment and leveling of the steel shuttering plates during the construction process. Use a spirit level or laser level to ensure that the plates are straight and in the correct position. Any deviations or discrepancies should be corrected immediately to maintain the accuracy and integrity of the formwork.

Step 8:

Pour and Cure the Concrete Once the steel shuttering plates are securely in place and properly aligned, you can proceed with pouring the concrete. Ensure that the concrete is mixed and poured according to the project specifications. After pouring, allow the concrete to cure and set as per the recommended time frame before removing the steel shuttering plates.

Step 9:

Dismantle the Formwork After the concrete has sufficiently cured, carefully dismantle the steel shuttering plates. Start by removing the reinforcement materials, followed by the interlocked plates in the reverse order of installation. Handle the plates with care to prevent any damage and ensure their reusability for future projects.

By following these step-by-step instructions, you can effectively apply steel shuttering plates for your construction project. Remember to prioritize safety and quality throughout the process, ensuring the successful completion of your concrete structures.

Send Your Inquiry Now

FAQ

1. How long is your steel shuttering plate’s delivery time?

In General, the Delivery Time for the normal size of steel shuttering plate can be 3-4 weeks.

But if the steel shuttering plate is OEM Item, it will take a longer time around 4-8 weeks accordingly.

In a word, The steel shuttering plate products will be delivered as soon as possible on the basis of quality assurance.

2. How can I get your steel shuttering plate quotation as soon as possible?

We’ll send you the steel shuttering plate quotation by email.

Please give us your requirements, order information, and specifications (steel grade, size, quantity, and port of destination) for the steel shuttering plate, we will work out the moderate price of the steel shuttering plate within 24 hours after your inquiry.

3. How is the quality of your steel shuttering plate products?

Our steel shuttering plate products are manufactured strictly according to national and international standards, and our QC will make an inspection for steel shuttering plates before delivery.

If you want to see our quality certifications and all kinds of testing reports of the steel shuttering plate, please just contact us directly.

4. How much is the price of a Steel Shuttering Plate?

The price of the Steel Shuttering Plate will be calculated according to the size and weight normally.

It is necessary to check the real-time exchange rate and the market price of raw materials before providing you with the price of the Steel Shuttering Plate.

5. What is Steel Shuttering Plate?

Steel Shuttering Plate means the surface of the form and framing used to contain and shape wet concrete until it is self-supporting.

Steel Shuttering Plate includes the forms on or within which the concrete is poured and the frames and bracing which provide stability.

6. How can I choose specifications about Steel Shuttering plates?

You can tell us the height of your building or we can give you a suitable specification based on our experience in your market.

We also provide several sizes of Steel Shuttering plates for you to choose from.

7. What kind of project is more suitable for steel shuttering plates?

The steel shuttering plates are very suitable for large concrete construction projects and can be reused to create repetitive structures.

8. How does steel shuttering plate maintain its value?

Steel is the most common type of engineering steel shuttering plate, and there are many types of shuttering plates on the market, with many new and second-hand options.

Since the steel shuttering plate can be reused thousands of times, steel can retain its value well.

9. Compared with traditional formwork, what are the advantages of steel shuttering plate?

Compared with traditional formwork, steel shuttering plate does not absorb water, so honeycombs occur less frequently.

The steel shuttering plate is more durable, stronger, and stronger.

10. What is a steel shuttering plate?

The steel shuttering plate is sold well in the African market.

The standard specification of the steel shuttering plate is 450*1200*40, which is mostly used in pouring roofs or other scenes.

The steel shuttering plate is light in weight, easy to operate, and can be reused.

Common colors of the steel shuttering plate are red or blue.

11. What is the cost of a steel shuttering plate?

The Price of the steel shuttering plate is according to the specifications and quantity.

Our steel shuttering plate weight is calculated according to per square meter and the thickness of the comprehensive consideration, usually in 30-40 kg/m2.

If The steel shuttering plate is not a regular length, like 2.5 m, then it is necessary to change the calculation and consider whether a reinforcing pipe should be added to achieve the required bearing force.

Please send the specifications and quantity of the steel shuttering plate you need for our reference first.

12. What is the thickness range of the steel shuttering plate?

The thickness of the steel shuttering plate is between 2-6mm.

The thickness of the steel shuttering plate should be matched according to the required specifications by the customer.