Steel Forms Manufacturer

Steel Forms are commonly made of Steel construction & casting is of prime importance concrete industry.

It is artificial support provided below and around the precast or cast-in situ concrete work.

Advantages :

- Great reusability.

- Steel Forms are durable and strong.

- Easy to fix the Formwork and also easy to dismantle.

- Provides a uniform and smooth surface finish to the structure.

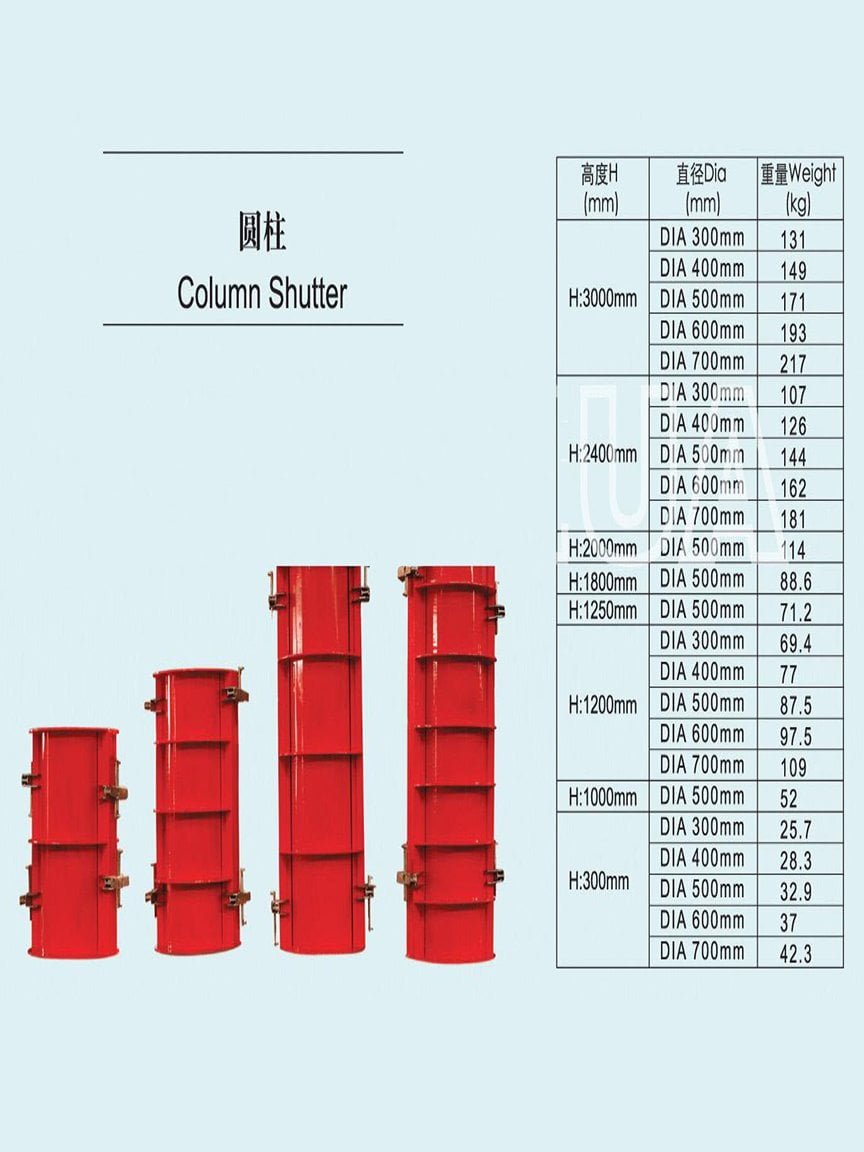

- Column Steel Forms Types

- Steel Forms Test Report

Steel Forms Basic Information

Steel Forms can replace wooden formwork, which significantly reduces the elimination of pore water pressure and air bubbles in concrete pressure

After the concrete is poured into a shape, an ideal rough interface is formed. No rough work is required to proceed to the next process of construction

Steel Forms can be placed before or after installing the rebar. If it is placed before installing the steel bar, it is convenient and easy to place and install;

The concrete pouring process can be visually monitored, thereby reducing the risk of pores and honeycomb structures.

Steel Forms Classification

1. Purpose: Civil construction (house construction) Steel Forms and Bridge Steel Forms.

2. Shape: Box Girder Steel Forms, T-beam Steel Forms, Cover Beam Steel Forms, Hollow Beam Steel Forms, Round Steel Forms, Protective Beam Steel Forms, Pier Column Head Steel Forms, etc.

3. Combination: Large Steel Forms, Small Steel Forms, Medium Steel Forms, Internal Corner Steel Forms, External Corner Steel Forms and so on.

Steel Forms Regular Size

Steel Flat Steel Forms (more sizes available) | |||||

| Code | Length(mm) | Width (mm) | Height (mm) | Thickness (mm) | Suface Treatment |

| F3018 | 1800 | 300 | 55 | 3 | painted |

| F3012 | 1200 | 300 | 55 | 3 | painted |

| F3006 | 600 | 300 | 55 | 3 | painted |

| F2018 | 1800 | 200 | 55 | 3 | painted |

| F2009 | 900 | 200 | 55 | 3 | painted |

| F2006 | 600 | 200 | 55 | 3 | painted |

| F1218 | 1800 | 120 | 55 | 3 | painted |

| F1209 | 900 | 120 | 55 | 3 | painted |

| F1206 | 600 | 120 | 55 | 3 | painted |

| F1015 | 1500 | 100 | 55 | 3 | painted |

| F1009 | 900 | 100 | 55 | 3 | painted |

| F1007 | 750 | 100 | 55 | 3 | painted |

Outer Corner Steel Forms (more sizes available) | |||||

| Code | Length(mm) | Flange height | Height (mm) | Thickness (mm) | Surface Treatment |

| CF0518 | 1800 | 100×150 | 55 | 3 | painted |

| CF5515 | 1500 | 150×150 | 55 | 3 | painted |

| CF0506 | 600 | 100×150 | 55 | 3 | painted |

Comer Angle Steel Forms (more sizes available) | |||||

| Code | Length(mm) | Flange height | Height (mm) | Thickness (mm) | Surface Treatment |

| CA0015 | 1500 | 50X50 | 55 | 3 | painted |

| CA0009 | 900 | 50X50 | 55 | 3 | painted |

| CA0007 | 750 | 50X50 | 55 | 3 | painted |

L Shape Corner Steel Forms (more sizes available) | |||||

| Code | Length(mm) | Flange Height (mm) | Height (mm) | Thickness (mm) | Surface Treatment |

| L1015A | 300 | 100*150 | 55 | 3 | painted |

| L1515B | 350 | 150*150 | 55 | 3 | painted |

| L1515C | 400 | 150*150 | 55 | 3 | painted |

Square Corner Steel Forms (more sizes available) | |||||

| Code | Length(mm) | Flange Height(mm) | Height (mm) | Thickness (mm) | Surface Treatment |

| L1015A | 300 | 100*150 | 55 | 3 | painted |

| L1515B | 350 | 150*150 | 55 | 3 | painted |

| L1515C | 400 | 150*150 | 55 | 3 | painted |

FAQ

1. How much do steel forms weigh?

The weight of the steel forms is determined according to the specifications.

The larger the steel forms, the thickness needs to be increased accordingly to achieve the proper bearing capacity, and the calculation methods of the adjustable steel forms and the flat steel forms are also different.

2. Why use steel forms?

When pouring concrete, steel forms are usually used for reinforcement and shaping. This is a popular choice for many reasons, including:

1. It will not bend or warp when pouring concrete.

2. It can be recycled 200-300 times.

3. Provide a uniform and smooth finish for the concrete surface.

4. It is easy to fix during use to ensure safety.

5. Easy to disassemble.

3. Why choose TSX Steel Forms?

As our main product, steel forms has received wide acclaim since its launch and has solved many problems in the project for customers in many countries.

Whether it is quality, analysis of drawings, price, or after-sales service for the Steel Forms, we do not seek to be the first in the world.

Instead, we are committed to providing every customer with an economical and suitable solution for Steel Forms.

At present, our steel forms are exported to South America, Africa, and many other countries. The monthly output can reach more than 1,000 tons.

The complete Steel Forms production chain ensures sufficient supply.

4. Why do builders prefer Steel forms?

The Steel forms are fixed together with large steel plates and steel bars, which are called brackets.

For builders, the use of steel forms is a good choice because the steel will not bend, warp, or otherwise deform during the concrete curing process.

5. How do the Steel forms improve stability?

These Steel forms can also be stacked to create higher structures.

The Steel forms can be interlocked, and scaffolding can hold the panels together for added stability.

6. Why use a Steel forms system?

When pouring concrete, steel is often used for Steel forms and reinforcement.

Steel forms is a popular choice for a variety of reasons, including:

Steel forms Will not bend or warp when pouring concrete.

Steel forms can be used multiple times.

Steel forms Provide a uniform and smooth finish for the concrete surface.

Steel forms are Easy to fix the template.

Steel forms are Easy to disassemble.

7. What are your payment terms for the Steel forms?

T/T 30% in advance, T/T 70% before loading the container is based on FOB Delivery Term.

T/T 30% in advance, T/T 70% upon sending the copy of Bill of Loading if based on CIF Delivery Term.

L/C 100% at Sight based on CIF Delivery Term.

Negotiate according to the order status.

8. Are you a manufacturer or trader for Steel Forms?

We are a professional manufacturer of the Steel Forms, with a history of ten years.

Besides the Steel Forms Factory, We also have a Scaffolding Factory covering different kinds of scaffolding products.

9. How fast can my steel forms order be delivered?

You can state your desired Delivery date for your steel forms order.

The steel forms order and the desired delivery date will be checked after your steel forms order is finalized.

After receiving your steel forms order Deposit, the estimated delivery time will be informed. Generally, it will take around 3-4 weeks after finalizing the Steel Forms Order.

If you have any special Delivery Time for the Steel Forms, Please tell us ahead, and we will try our best to meet your delivery date request.

10. What are Metal Steel Forms?

Steel Forms means the surface of the form and framing used to contain and shape wet concrete until it is self-supporting.

Metal Concrete Steel Forms include the forms on or within which the concrete is poured and the frames and bracing that provide stability.

11. How can I choose specifications for Steel Forms?

You can tell us the height of your building or we can give you a suitable specification for the steel forms based on our experience in your market.

We also provide several sizes of Steel Forms for you to choose from.

12. How much is the price of Steel Forms?

The price of steel forms is not fixed, it will be calculated according to the size and weight.

It is necessary to check the real-time exchange rate and the market price of raw materials when you request the steel forms’ price.