Concrete Metal Forms

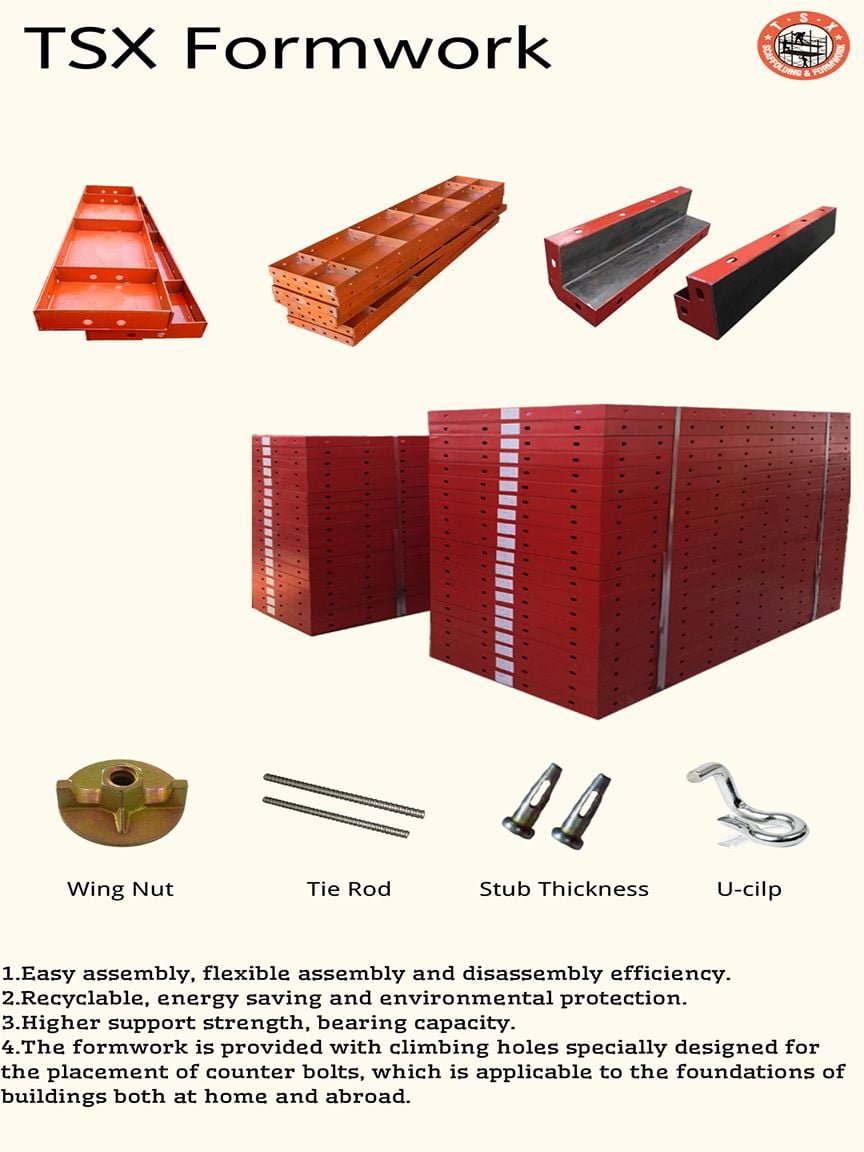

The characteristic of the Concrete Metal Forms is to fix the large steel plate and steel bar, tie rod or U clip and other accessories together, which is called “Concrete Metal Forms”.

Its function is to use concrete metal forms when pouring concrete to help cool the liquid form of the concrete into the desired shape.

Advantages of Concrete Metal Forms

- Reused about 200-300 times

- The concrete metal forms is sturdy and durable

- Provide a uniform and smooth surface finish for the structure

- The concrete metal forms is easy to fix and also easy to disassemble

- Concrete Metal Forms-Hot Countries

- Concrete Metal Forms-Hot Style

Types of Hot-Selling Concrete Metal Forms

The Basic Requirements Of a High-Quality Concrete Metal Forms

The material of the concrete metal forms should be structurally stable and can effectively support the liquid concrete in both horizontal and vertical directions. At the same time, its strength should be sufficient to withstand all types of static and live loads.

The joints between the concrete metal forms should be tightly connected by accessories to ensure that the cement slurry is prevented from leaking, which will damage the shape and aesthetics of the building.

At the same time, during the construction process, when the concrete metal forms are removed, the demolished concrete metal forms will not have any influence on the already formed concrete, which plays a role of reuse.

On the basis of ensuring the bearing capacity, the concrete metal forms should be more portable and convenient for workers to construct.

FAQ

1. Can you supply other concrete metal forms products?

Yes. All related concrete mental forms products.

a.Flat concrete metal forms

b.Corner concrete metal forms

c.Round column concrete metal forms

d.Square column concrete metal forms

e.Steel-wood concrete metal forms.

2. Can I visit your factory to inspect the concrete metal forms for the order?

Welcome to my company, and we expect to build long-term cooperation with you and will provide the qualified concrete metal forms.

3. How to buy your concrete metal forms?

You can provide us with your drawing for the concrete metal forms, and we will produce your drawing.

4. Can you reuse Concrete Metal Forms?

Yes.

You can purchase the Concrete Metal Forms once, and reuse them over 100 times.

In other words, the reusable Concrete Metal Forms will save you money and time again.

5. How much is the price of Concrete Metal Forms?

The price of the Concrete Metal Forms is calculated according to the size and weight.

The price is not fixed.

It is necessary to check the real-time exchange rate and the market price of raw materials.

6. How long do Concrete Metal Forms need to be in place?

The Concrete Metal Forms or “molding” that holds the concrete in place until it dries should be left alone for at least two days to ensure that the concrete is completely dry.

If the Concrete Metal Forms are removed too soon, the concrete can begin to sag, crack and collapse, especially if conditions like temperature affect its strength.

7. Can the Concrete Metal Forms be removed in advance?

No. If the Concrete Metal Forms are removed prematurely, the concrete may begin to sag, crack and collapse, especially when temperature and other conditions affect its strength.

8. Where are steel Concrete Metal Forms mainly used?

The panels can be mass-produced in any desired modular shape or size. Steel Concrete Metal Forms is mainly used for large-scale projects or situations where Concrete Metal Forms can be reused in large quantities.

This type of steel Concrete Metal form is considered the most suitable for round or curved structures.

9. Comparison of steel Concrete Metal Forms and wood Concrete Metal Forms

a. Steel Concrete Metal Forms is stronger, more durable, and has a longer lifespan than wood Concrete Metal Forms, and it is reused more often.

b. The installation and disassembly of steel Concrete Metal Forms are more convenient and quick.

c. The exposed concrete surface with steel Concrete Metal Forms is of good quality and no further treatment is required.

d. The steel Concrete Metal Forms does not absorb the moisture in the concrete.

e. The steel Concrete Metal Forms does not shrink or warp.

10. How much do concrete metal forms weigh?

Regarding the weight of the concrete metal forms, it should be determined according to the specifications.

For example, the width of the flat concrete metal forms is less than 300mm, and the calculation is 40kg per square meter.

The larger the width, the bearing capacity should be considered, and the weight should be increased accordingly.

11. Where can I apply Concrete Metal Forms?

Concrete Metal Forms can have many forms, such as being applied to a drainage ditch, the foundation of a building, guardrail beside the road, building sidewalk, etc.

12. Is it cheaper to build with Concrete Metal Forms or wood?

Although wood is a cheaper alternative than concrete metal forms, it ages faster and has higher maintenance and repair costs.

Overall, concrete’s resistant properties result in a lower cost of maintenance over the lifespan of the structure.

So we suggest the Concrete Metal Forms which can longer the using life and can be reused around 100-200 times.

Concrete Metal Form-Hot

Types of Hot-Selling Concrete Metal Form

Concrete Metal Form