Scaffold Props Production Line

- Mechanical cutting the Scaffold Props Pipe to minimize the deviation.

- Uniform mechanical drilling to ensure proper hole spacing in the Scaffold Props.

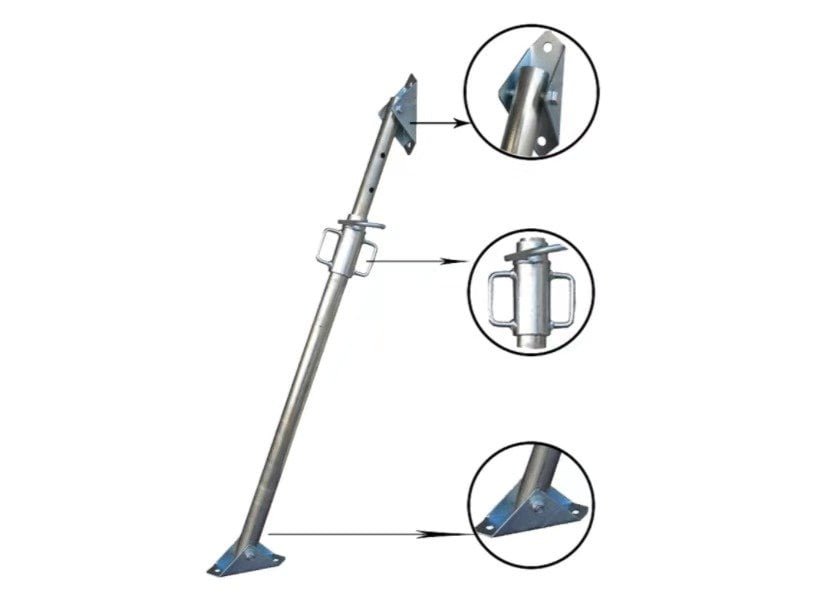

- Welding the Scaffold Props top & base plate and the screw for easy adjustment and support.

Types of Scaffold Props For Sale

TSX-a company that has been manufacturing scaffold props suitable for all workplace needs for ten years

The following are six styles of scaffold props used in construction and various support systems

TSX Scaffold Props Customized Product

Fix the hole position on the screw of the Scaffold Props to fine-tune the height.

Laser cut the scaffold props tube to directly adjust the height using an hydraulic pump.

FRP Scaffold Props Mainly used in Electricity Industry, the material is FRP(Fiber Reinforced Plastics) to protect the safety of workers.

Scaffold Props Head Plate Sizes

T Head(mm) : Length – 540

Square Plate(mm) : Width*Length*Thick – 120*120*4

U Head (mm) : Width*Length*Height*Thick – 120*110*45*5

Scaffold Props Producing Processes

- Accessories Of Scaffold Props

- Scaffold Props Packing

The scaffold props do not only have the characteristics of a wide application range and strong bearing capacity but also can effectively reduce the number of scaffold props and construction costs.

The most important thing is that the distance between the scaffold props and the cross beam can be adjusted in time according to the load of the beam, without being restricted by the horizontal connecting rod.

Establishing a safe construction site requires strict compliance with various standards, which can be seen from the selection of materials used on the construction site, take the Scaffold Props as a sample.

This is also the scaffold props quality that We-TSX has been strictly implementing and continuously optimizing for the safety of our customers, and similarly, for our customers’ clients.