Shuttering In Construction

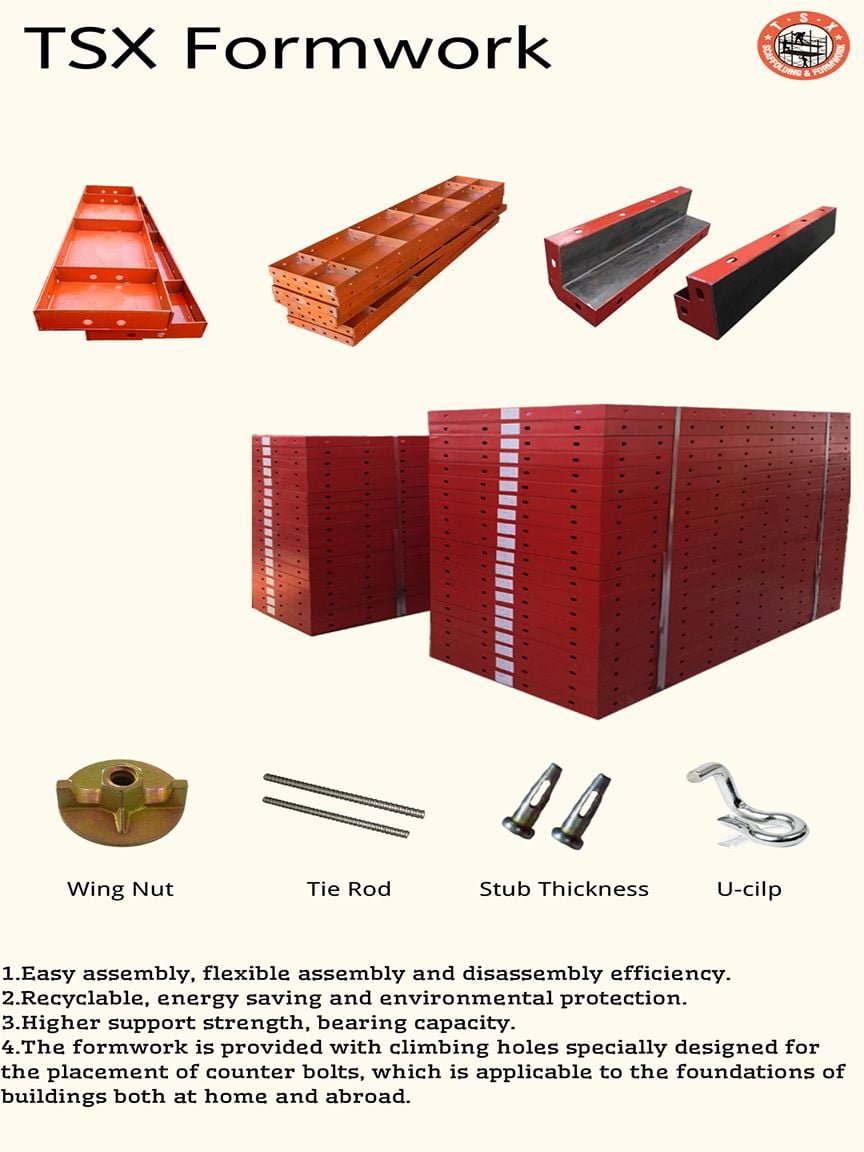

The Shuttering In Construction is made of steel, and the steel material will not be deformed due to water seepage, so it has good economic benefits. There are many types of Shuttering In Construction, such as

- Flat Shuttering In Construction

- Steel Shuttering In Construction

- Steel-wood Shuttering In Construction

- Round Column Shuttering In Construction

- Square Column Shuttering In Construction

- Accessories Of Shuttering In Construction

- Packing Of Shuttering In Construction

Types Of Shuttering In Construction

Shuttering In Construction

There is no doubt that Shuttering In Construction is essential for any building. Its main advantage is that it cannot be replaced by any other technology. The use of Shuttering In Construction concrete structures can be constructed quickly and in the most economical way. During the entire construction period, the Shuttering In Construction provides proper passages and working platforms, which greatly improves worker safety.

The Shuttering In Construction helps to shorten the timetable and cost of the project by reducing the floor-to-floor construction cycle time, which means that more projects can meet their budget needs.

The Shuttering In Construction helps the construction manager to provide accurate template resources to open and remove the mold on time, thereby improving project efficiency and resource utilization.

The Shuttering In Construction can provide good structural safety for all solutions that cover the load, thereby producing a very safe and practical structure.

FAQ

1. What are the types of Shuttering In Construction?

①Steel Shuttering In Construction

②Flat Shuttering In Construction

③Corner Shuttering In Construction

④Column Shuttering In Construction

⑤Steel-wood Shuttering In Construction

2. What is Shuttering In Construction?

Shuttering is used to describe the process of building temporary molds in which fresh concrete is poured to construct designated structural concrete elements and achieve its shape.

3. What are the requirements for Shuttering In Construction?

①The Shuttering is strong enough to bear all types of loads.

②The Shuttering is hard enough to maintain its shape.

③The Shuttering joints are tight to prevent the cement slurry from leaking.

④The Shuttering should allow the various parts to be dismantled in the required order without damaging the concrete.

⑤The Shuttering material should be cheap, easily available, and reusable.

⑥The Shuttering should be accurately set to the required line, and the horizontal plane should have a flat surface.

4. What is a shutter in construction?

Shutter In Construction is molded for freshly poured concrete, in which concrete is poured and cast into the required shape to obtain initial strength, hardening and maturity.

5. What is Shutter material In Construction?

Shutter material may be made from plywood. The process of shuttering involves setting up temporary structures that will act as molds for concrete as it sets. Shuttering material may include panels, precast molds, and various fastening and support devices known as falsework.

6. Which type of Shuttering In Construction is best?

Steel Shuttering is needed for both big and small projects In Construction. Concrete has outstanding properties. This makes it ideal for all types of construction works.

7. What is Shuttering In Construction?

Shuttering In Construction is defined as the temporary molds that are used to hold the wet concrete in place until the concrete has set and cured. Projects of different sizes will often need to use both formwork and Shuttering In Construction.

8. When should I remove Shuttering In Construction?

Normally, walls, columns, and other vertical Shuttering In Construction can usually be removed after 24 to 48 hours.

If you use quick-drying cement, this may take up to 12 hours. However, for large buildings, the Shuttering In Construction can generally be removed after 3 days, and the pillars can be removed after 2 weeks.

These are only suggested times. Before demolition, you need to check whether the concrete surface has been air-dried before further processing.

9. How long can walk on the Shuttering In Construction after pouring it?

After 24 hours, you can walk on the newly poured Shuttering In Construction. Before walking, please use a tool to test whether the concrete has completely solidified. During walking, avoid dragging your feet or objects with sharp objects, as they will damage the surface of the Shuttering In Construction.

10. How to extend the life of the Shuttering In Construction?

-Don’t drive too many nails on Shuttering In Construction.

-Only use as much wood, brackets, tethers, etc. as needed.

-Shuttering In Construction Consider which plank, panel, or square timber to peel off first, and fix them so that they can be easily removed in the correct order.

11. What are the advantages of Shuttering In Construction?

The advantage is to save time. By reducing floor-to-floor construction time, Shuttering In Construction helps reduce project construction time.

In addition, Shuttering In Construction play a vital role in meeting budget requirements and reducing costs.

The use of Shuttering In Construction helps project managers to promote the timely mobilization and demobilization of template resources, thereby further reducing costs and improving efficiency.

12. Where is steel Shuttering In Construction mainly used?

The panels can be mass-produced in any desired modular shape or size. Shuttering In Construction is mainly used for large-scale projects or situations where Shuttering In Construction can be reused in large quantities.

This type of Shuttering In Construction is considered the most suitable for round or curved structures.

13. What kind of Shuttering In Construction is the best seller?

The best-selling Shuttering In Construction is the Middle Eastern type, which is 2.2m to 4m in size and is suitable for the US market, the UK market, some African markets such as Djibouti, Ghana, Uganda and some other countries.

14. When should I use Shuttering In Construction?

Generally, Shuttering In Construction are used for scaffolding or building support to aid in the completion of the following tasks or projects:

1. Shuttering In Construction are used in the construction or renovation of buildings

2. Shuttering In Construction are required to add Windows, doors, or arches to walls

3. Shuttering In Construction is used to install reinforced beams and concrete parts.

4. Shuttering In Construction are used as supports for stairs, columns, and wall formwork

15. How many Shuttering In Construction can fit in a 20 ft container?

If it’s a flower plate, it usually holds 2020 pcs Shuttering In Construction and up to 2,200pcs Shoring If it is a square plate, it usually holds 1500 pcs Shuttering In Construction and up to 1750 pcs Shuttering In Construction

Concrete Metal Form-Hot

Types of Hot-Selling Concrete Metal Form

Concrete Metal Form