Advantage of Formwork For Construction

- Formwork For Construction is stronger, durable and have longer life Span

- Formwork For Construction can be installed and dismantled easily with great speed.

- It is cost-effective if construction is going on in large quantity.

- Formwork For Construction do not absorb water or moisture from Concrete.

- This type of Formwork For Construction doesn’t shrink or warp.

- The quality of the concrete surface by Formwork For Construction is smooth, and it doesn’t require any further treatment.

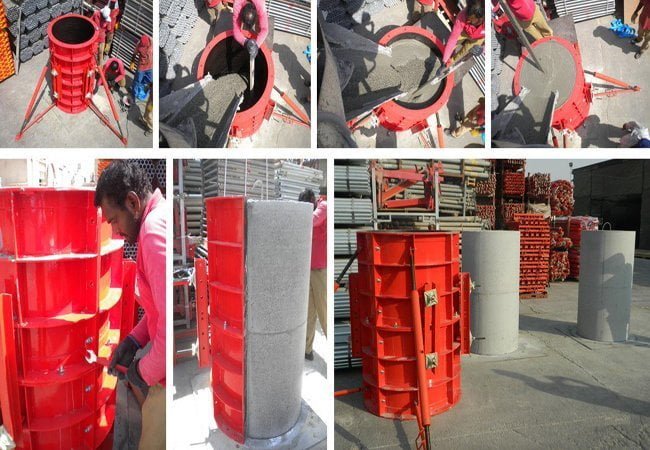

- Manufacturing of Formwork

- Packing of Formwork For Construction

Types of Formwork For Construction

The joints in the Formwork For Construction is tight against leakage of cement grout.

Formwork For Construction is strong enough to withstand all types of dead and live loads.

The material of the Formwork For Construction is cheap, readily available, and suitable for reuse.

The material of the Formwork For Construction is not warp or get distorted when exposed to the elements.

Formwork For Construction used in the industry must be designed, fabricated, erected, supported, braced, and maintained so that it can support all vertical and horizontal loads that will be exerted. Here are the safety precautions to follow when dealing with Formwork For Construction.

FAQ

1. What is Formwork For Construction?

Formwork For Construction means the surface of the form and framing used to contain and shape wet concrete until it is self-supporting.

Formwork includes the forms on or within which the concrete is poured and the frames and bracing which provide stability.

2. How can I choose specifications about Formwork For Construction?

You can tell us the total area of your project and we can match Formwork to you.

You can also just tell us the length and width you need. We will provide you with a quotation.

3. Formwork For Construction introduction:

Formwork For Construction is the name of the mold used to create walls, columns, floors, stairs, and other concrete structures.

Freshly Formwork For Construction poured concrete (a mixture of sand, gravel, cement, and water) is wet, so it cannot support its own weight or maintain its shape.

The Formwork For Construction supports the weight of the concrete until it dries into a specified shape and gains the strength to support itself.

4. In most construction projects, how much budget does Formwork For Construction account for?

Formwork For Construction accounts for about 40% to 60% of the specific budget of a project.

And the materials actually only account for a small part of the cost of the Formwork For Construction.

Most of the money is spent on the labor of Formwork For Construction assembly and disassembly.

5. What is the steel Formwork For Construction made of?

The steel Formwork For Construction is a plate composed of thin steel plates.

Steel Formwork For Construction is very common now because it provides you with a longer life cycle and provides you with better replication.

Formwork For Construction necessary clamps, nuts, and bolts can be used to install the steel plate unit together. Steel plates can be manufactured in modular form or on a scale.

6. What is the production process of the Formwork For Construction?

1)Choosing Material of the Formwork For Construction and Cutting.

2)Bending the edge of the Formwork For Construction.

3)Second Bending of the Formwork For Construction(Same Height to the Rib).

4)Rib Cutting, Punching Hole, and Bending of the Formwork For Construction(As the Client’s Request).

5)Assembling and Welding of the Formwork For Construction.

6)Painting of the Formwork For Construction.

7)Packing of the Formwork For Construction.

7. What is Formwork For Construction?

The Formwork For Construction shapes the concrete into the required size and shape and controls its position and alignment.

The Formwork For Construction is a temporary structure that can support its own weight and newly poured concrete, as well as construction live loads including materials, equipment, and workers.

8. What is the most common type of Formwork For Construction?

The most common style is flat Formwork For Construction.

The existing popular types such as corner Formwork For Construction, column Formwork For Construction, special-shaped Formwork For Construction, cylindrical Formwork For Construction, bridge Formwork For Construction and culvert Formwork For Construction, etc.

The foundations of these types of Formwork For Construction are all established by flat Formwork For Construction.

Just need to add additional support to reach the corresponding load-bearing capacity.

9. What are the advantages of Formwork for Construction?

Formwork for Construction can play an important role in concrete construction, acting as a mold for poured concrete.

Formwork for Construction can be used always as a mold, which holds the poured concrete in shape until it hardens and gets enough strength to support itself.

10. Why formwork for construction is used?

Formwork for Construction is linked tightly with concrete structure’s surface finishing – the finer quality of Formwork for Construction used, the better will be the surface finishing.

Formwork for Construction provides excellent structural safety by offering methods against all overlay loads, producing extremely safe and practical structures.

11. What are the materials used in Formwork for Construction?

Using steel in Formwork for Construction adds to the initial cost, but it proves economical in the long run because it can be reused many more times, often ten times more than wood formwork.

After using steel Formwork for Construction, there is less further finishing as it provides an excellent exposed concrete surface.

12. Why do I need a Formwork For Construction?

In the process of building construction, the use of Formwork For Construction is very necessary. There are many types of Formwork For Construction, which are very important in construction. The type of Formwork For Construction can meet various needs in the construction process.

13. What is the use of Formwork For Construction?

The Formwork For Construction is used as a mold for concrete structural parts.

At this stage, fresh concrete is usually poured into the shape Formwork For Construction specified in the drawing.

14. Can I reuse concrete Formwork For Construction?

Yes, our Formwork For Construction can be reused, will not cause waste of resources, and save costs.

15. What are the advantages of Formwork For Construction?

Such concrete structural Formwork For Construction often includes custom solutions that require skilled workers.

This type of Formwork For Construction usually offers high safety, fast field construction, and cost savings.