Advantage of Formwork For Concrete

- Joints that are tight enough to prevent leakage.

- Use available equipment to handle safely and easily.

- Stable enough in all weather conditions-it should not warp or deform when exposed to the natural environment.

- The structure is sturdy, effectively supporting and supporting the horizontal and vertical directions to maintain the shape.

- Manufacturing of Formwork For Concrete

- Packing of Formwork For Concrete

With our formwork for concrete bracing for concrete systems, you’ll enjoy many benefits that just wouldn’t be possible with timber formwork for concrete. Just some of the advantages are listed below:

- More efficient formwork for concrete

- Can be used on uneven surfaces formwork for concrete

- Straighter edges, including when forming brick ledge formwork for concrete

FAQ

1. What are the types of Formworks In Construction?

Types of Formworks In Construction:

①Flat Formworks In Construction.

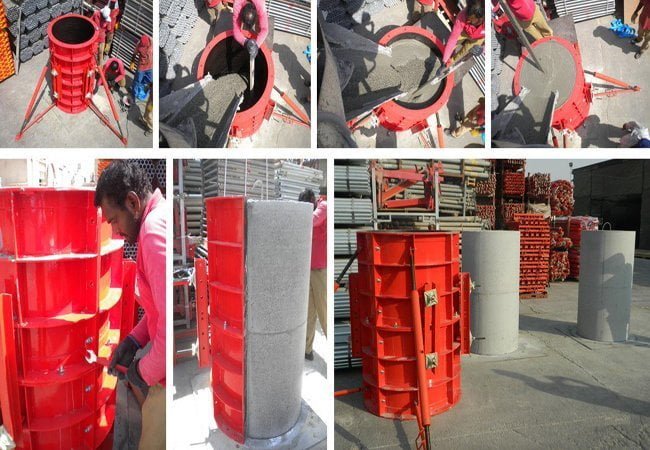

②Square Column Formworks In Construction.

③Round Column Formworks In Construction.

④Steel-wooden Formworks In Construction.

2. What is a Formworks In Construction?

Formworks In Construction is a temporary or permanent mold into which concrete or similar materials are poured.

In concrete construction, Steel Props are used to support the Formworks In Construction.

3. What are the advantages of Formworks In Construction?

①The Formworks In Construction is strong enough to withstand various dead and live loads.

②The Formworks In Construction can maintain its shape without shifting.

③The joints in the Formworks In Construction are tight enough to prevent the cement slurry from leaking.

4. What is Formworks in Construction

Formwork in construction is used to hold the shape of the concrete until it is hardened. It is a model used to hold poured concrete until it achieves its initial strength.

There are different types of forms used in the construction industry depending on the type of material, manufacture, and use.

5. Is this important to use Formworks in Construction?

In construction today, we normally need Formworks in Construction for the foundation, column, tie beam, suspended slab, etc.

A project without this model will prevent you from working on the site and may even cause delays if the model is not immediately available during formwork in construction.

Extra care of using formworks in Construction because it can cause cracking of concrete after pouring.

6. What is the difference between Formworks in Construction and Scaffolding?

Formwork in Construction is the surface of formwork and frame used to hold and shape wet concrete until it is self-supporting.

Scaffolding includes foundations, bases, and all structural members supporting permanent structural members.

7. What are the main parts of the Formworks In Construction?

The Formworks In Construction can be named according to the construction type of the structural member, such as the flat formwork for the floor, the beam Formworks In Construction, the column Formworks In Construction for beams and columns, the special Formworks In Construction for culverts, and the bridge Formworks In Construction.

The specific type of the Formworks In Construction needs to be determined according to the needs of the building.

8. What conditions should the Formworks In Construction have?

Formworks In Construction should be strong enough to withstand the corresponding degree of load-bearing capacity.

The joints of the Formworks In Construction should be tight to prevent the cement slurry from leaking.

Formworks In Construction should allow the various parts to be removed in the required order without damaging the concrete.

The material of the Formworks In Construction should be suitable for repeated use.

Formworks In Construction should be accurately set to the required line, and the horizontal plane should have a flat surface.

Formworks In Construction should be as light as possible.

Formworks In Construction material should not be warped or deformed when exposed to the natural environment.

9. How to remove the Formworks In Construction?

1)First remove the Formworks In Construction on the vertical sides of the walls, beams, and columns because they no longer bear the load and only retain the concrete.

2)Next, Formworks In the Construction of the slab should be removed to form the soffit.

3)Finally, Formworks In Construction soffits of beams, girders, or other heavy-duty formwork should be removed.

At the same time, the fast-hardening cement, warm weather, and light-load conditions allow the Formworks In Construction to be removed in advance.

In the process of removing the building Formworks In Construction, extra care should be taken to prevent the load from being suddenly transferred to the concrete.

10.The significance of Formworks In Construction in today’s construction industry.

There are many reasons why Formworks In Construction are important, but a good reason is that Formworks In Construction cannot be replaced by any other technology.

Using formwork in Construction, concrete structures can be quickly constructed in the most affordable way.

11. What role did the Formworks In Construction play in the entire construction phase?

Throughout the construction phase, the Formworks In Construction provides a proper passage and working platform, which greatly improves the safety of workers’ scaffolding.

Formworks In Construction greatly shortens the time and cost of the project by shortening the floor-to-floor construction cycle, which means that more projects can meet their budget needs.

Formworks In Construction helps the construction manager to mobilize and release template resources in an accurate and timely manner, thereby improving project efficiency and resource utilization.

12. How to distinguish between good and bad Formworks In Construction on the surface?

Formworks In Construction is related to the surface treatment of the concrete structure-the better the quality of the Formworks In Construction used, the better the surface treatment.

The formwork in Formwork provides excellent structural safety by providing solutions for all covered loads, resulting in a very safe and practical structure.

13. What are the advantages of Formworks In Construction?

Formworks In Construction is fast becoming one of the most recognized formwork types due to its many benefits, including low ecological footprint and low cost.

Formworks In Construction can be built quickly, is fire-resistant, durable, and provides enhanced sound insulation and insulation.

Usually assembled on-site, this formworks in Construction type remains after the concrete has hardened.

14. Are Formworks in construction safe?

Yes, Formwork in construction provides superior structural safety by providing solutions for all overlay loads, resulting in exceptionally safe and practical structures.

15.How to judge the quality of Formworks?

Formworks In Construction is associated with concrete structure s surface finishing the finer the quality of formwork used, the better will be the surface finishing.