Suspended Concrete Slab Systems

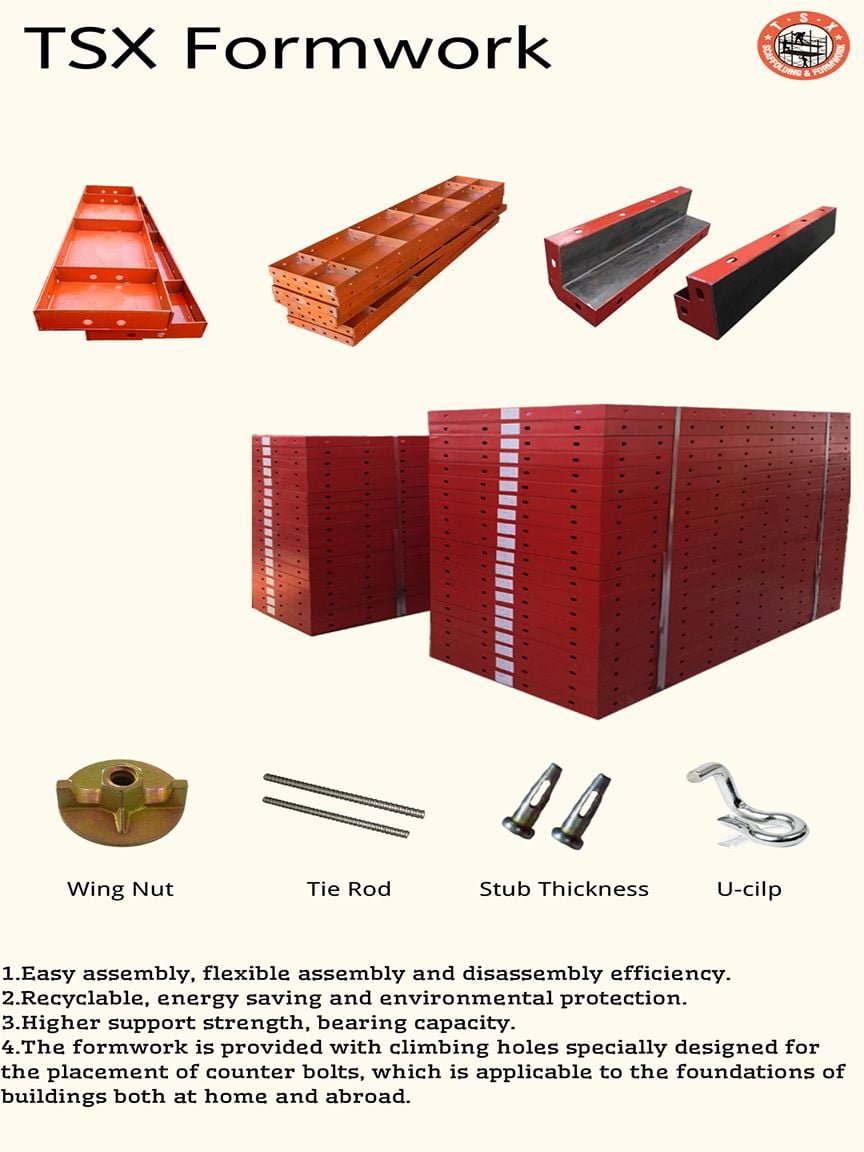

Good formworks should meet the following requirements:

1. Suspended Concrete Slab Systems should be sufficient strength.

For example, self-weight, the weight of steel bars, the weight of wet concrete, worker’s load, and any other load during and after concrete placement.

2. Suspended Concrete Slab Systems should be inflexible construction and effective support and support to maintain their shape without excessive deflection.

3. The joints of the Suspended Concrete Slab Systems should be tight to prevent the cement slurry from leaking out.

- Suspended Concrete Slab Systems

- Suspended Concrete Slab Systems Test Report

Types of OEM Suspended Concrete Slab Systems

FAQ

1. What type of formwork belongs to Suspended Concrete Slab Systems?

The Suspended Concrete Slab Systems means the combination of acrow prop and formwork.

The acrow prop is not a conventional style but is a push-pull prop.

The meaning of the Suspended Concrete Slab Systems is that the push-pull prop supports the wall formwork, which is convenient for workers to pour concrete between the two wall formwork.

2. When to choose a Suspended Concrete Slab Systems?

There are many types of Suspended Concrete Slab Systems including the Suspended Concrete Slab Systems.

Suspended Concrete Slab Systems means that there is a certain space between the two sides of the formwork.

In the process of pouring concrete using the Suspended Concrete Slab Systems, it will expand outward due to tension and affect the final concrete shape, which may cause accidents in serious cases.

This requires choosing a Suspended Concrete Slab Systems to increase resistance.

3. How to match the number of acrow and Suspended Concrete Slab Systems?

In terms of quantity matching, it is necessary to take the specifications into account of the Suspended Concrete Slab Systems, the bearing capacity that needs to be reached, the same as the project budget.

If you need a Suspended Concrete Slab Systems, please feel free to contact us.

4. Why use a Suspended Concrete Slab Systems?

Suspended Concrete Slab Systems will not bend or warp when pouring concrete.

Suspended Concrete Slab Systems can be used multiple times.

Suspended Concrete Slab Systems provide a uniform and smooth finish for the concrete surface.

It is easy to fix the Suspended Concrete Slab Systems.

It is easy to disassemble the Suspended Concrete Slab Systems.

5. How long is the lifetime of Suspended Concrete Slab Systems?

If properly maintained, The Suspended Concrete Slab Systems can be last up to 5,00 work cycles.

6. Why the price of Suspended Concrete Slab Systems is high, but it is still the most economical formwork?

Although the price of steel Suspended Concrete Slab Systems is higher than the wood template, its excellent durability and the fact that Suspended Concrete Slab Systems can be reused many times make it so cost-effective.

7. Can the Suspended Concrete Slab Systems Products be reused?

Yes, The Suspended Concrete Slab Systems Products can be reused many times.

Suspended Concrete Slab Systems can be resold after the project is completed.

In other words, the reusable Suspended Concrete Slab Systems will save you money and time again.

8. How can I choose specifications about Suspended Concrete Slab Systems Products?

There are various specs for the Suspended Concrete Slab Systems.

The Suspended Concrete Slab Systems will be provided according to the project or construction request.

After more details about the Construction or Project provide, a suitable specification of Suspended Concrete Slab Systems based on our experience in your market.

9. How to ensure Suspended Concrete Slab Systems’ quality?

First of all, we have QC department to control the Suspended Concrete Slab Systems’ quality when producing and before the delivery.

Secondly, A third-party testing agency to verify our Suspended Concrete Slab Systems’ quality is also accepted.

10. What’s your Suspended Concrete Slab Systems’ MOQ?

Generally, the Suspended Concrete Slab Systems’ MOQ should be one full 40HQ Container.

But if the quantity of the Suspended Concrete Slab Systems for the first trial order is the last issue for this order, We will try to apply a 20ft container at the first cooperation first.

11. How long is your delivery time for the Suspended Concrete Slab Systems?

Generally, it is 7-14 days if the Suspended Concrete Slab Systems’ normal sizes are in stock.

It will take 3-4weeks if the Suspended Concrete Slab Systems are not in stock.

Of course, the different order quantities will influence the delivery time also.

12. What are your payment terms for the Suspended Concrete Slab Systems?

The payment for Suspended Concrete Slab Systems based on the CIF Delivery Term should be T/T 30% in advance, the 70% Balance against the copy of BL. Or 100% L/C at sight is also can be accepted.

The payment for Suspended Concrete Slab Systems based on the FOB Delivery Term should be T/T 30% in advance, the 70% Balance before loading the container.

13.How does The Suspended Concrete Slab Systems Meet The Load-Bearing And Height Requirements?

The welds of each template are at a right angle of 90 degrees to obtain maximum strength while maintaining the thickness of the entire plane without adding extra weight.

14.What is The Application Scope Of The Suspended Concrete Slab Systems?

The Suspended Concrete Slab Systems provide vertical strength and a foundation to which additional support products can be added. It also provides compatibility with other products, making it versatile and cost-effective to use. They can be used for building walls, bridges, sewers, etc.

15.How To Ensure The Safety Of Workers Using Suspended Concrete Slab Systems?

Do well in the training knowledge of the workers, and do not move the Suspended Concrete Slab Systems by yourself when using the Suspended Concrete Slab Systems by multiple people. Regularly check the lie of the Suspended Concrete Slab Systems