Products Description

A good formwork should meet the following requirements:

The formwork should have sufficient strength.For example, self-weight, weight of steel bars, weight of wet concrete, load of workers, and any other loads during and after concrete pouring.The formwork should have a rigid structure and effective support and bracing to maintain its shape without excessive deflection.The joints of the formwork should be tight to prevent cement slurry from leaking out.

Product Description

|

Type

|

Steel Formwork For Concrete Construction

|

||

|

MOQ

|

500 pcs

|

||

|

Color

|

Regular color is red , other coors are available

|

||

|

Packing

|

1*20ft: about 20tons (regular type steel formwork)

|

||

|

Material

|

Q235 steel

|

||

|

Thickness

|

3mm

|

||

|

Width of Rib

|

55mm

|

||

|

Surface Treatment

|

Painted

|

||

|

Prduction Capacity

|

10 tons per day

|

||

|

Details of Concrete Metal Formwork/Steel Formwork

|

|||

|

1.Concrete metal formwork is made of Q235 steel plate which is heavy/light duty formwork system for concrete wall, beam, slab and column.

|

|||

|

2.There are some ribs in the middle of metal formwork which can strengthen the formwork more steady.

|

|||

|

3.Coined edge can help to form a perfect concrete finish without bubbles.

|

|||

|

4.Metal formwork is spray painted to against rustiness which can be reusable for many times.

|

|||

|

5.Metal formwork is the all-round panel for many construction areas.

|

Application

Flat Form Parameters

Flat Forms – These are used for forming plane surfaces. They are fabricated into rectangular panels of various standard widths and lengths.

|

Code

|

Length(mm)

|

Width(mm)

|

Height(mm)

|

Thickness

|

|

F2018

|

1800

|

200

|

55

|

3

|

|

F2015

|

1500

|

|||

|

F2012

|

1200

|

|||

|

F2007

|

750

|

|||

|

F2006

|

600

|

|||

|

F3018

|

1800

|

300

|

55

|

3

|

|

F3015

|

1500

|

|||

|

F3012

|

1200

|

|||

|

F3007

|

750

|

|||

|

F3006

|

600

|

|||

|

F1518

|

1800

|

150

|

55

|

3

|

|

F1515

|

1500

|

|||

|

F1512

|

1200

|

|||

|

F1509

|

900

|

|||

|

F1506

|

600

|

|||

|

F1218

|

1800

|

125

|

55

|

3

|

|

F1215

|

1500

|

|||

|

F1209

|

900

|

|||

|

F1207

|

750

|

|||

|

F1206

|

600

|

|||

|

F1018

|

1800

|

100

|

55

|

3

|

|

F1015

|

1500

|

|||

|

F1012

|

1200

|

|||

|

F1007

|

750

|

|||

|

F1006

|

600

|

Inner Corner Form Parameters

Inner Corner Forms – These are used for forming inner right-angled corners of a structure

|

Code

|

DIMENSION(MM)

|

|

CF0518

|

100*1800*150

|

|

CF0515

|

100*1500*150

|

|

CF0512

|

100*1500*120

|

|

CF0509

|

100*900*150

|

|

CF0507

|

100*750*150

|

|

CF5518

|

150*1800*150

|

|

CF5515

|

150*1500*150

|

|

CF5512

|

150*1200*150

|

|

CF5507

|

150*750*150

|

|

CF5506

|

150*600*150

|

Corner Angle Form Parameters

Corner Angles – These are used for forming external angles by combining 2 flat forms into a right-angled corner.

|

CODE

|

DIMENSION

|

|

CA0015

|

50*150*50

|

|

CA0012

|

50*1200*50

|

|

CA0009

|

50*900*50

|

|

CA0007

|

50*750*50

|

|

CA0006

|

50*600*50

|

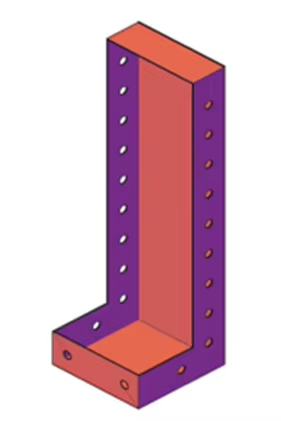

L-Shape Forms Paramaters

L-Shape Forms Paramaters-These are short inner corner forms for forming and short lengths of right-angle corners of structure .They consist of two form faces of various dimensions

|

CODE

|

DIMENSION

|

|

L1015A

|

100*300*150

|

|

L1015B

|

100*350*150

|

|

L1015C

|

100*400*150

|

|

L1015D

|

100*450*150

|

|

L1015E

|

100*500*150

|

|

L1515A

|

150*300*150

|

|

L1515B

|

150*350*150

|

|

L1515C

|

150*400*150

|

|

L1515D

|

150*450*150

|

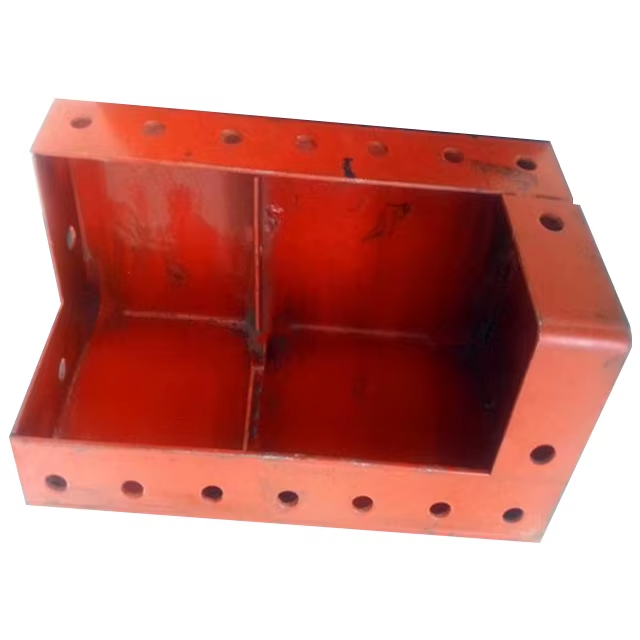

Square Corner Form

Square Corner Forms – These are used for connecting inner corner forms of L-shaped forms (S-Forms) at the intersection of 3 surfaces

|

CODE

|

DIMENSION

|

|

S1515A

|

150*300*150

|

|

S1515B

|

150*350*150

|

|

S1515C

|

150*400*150

|

|

S1515D

|

150*450*150

|

|

S1515AA

|

100*325*150

|

|

S1515BB

|

100*375*150

|

|

S1515CC

|

100*425*150

|

|

S1515DD

|

100*475*150

|

Packing & Delivery

Tags:

Technical parameter

Scenarios

Scenarios

Scenarios

Scenarios