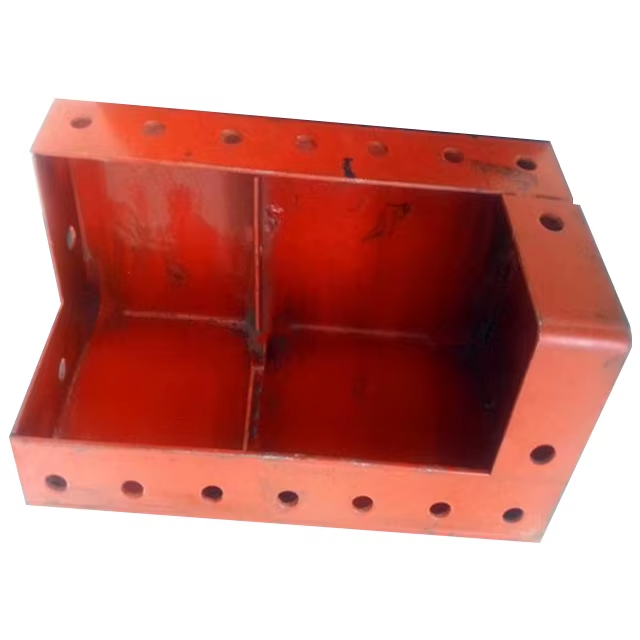

Products Description

Concrete Pit Formwork refers to the formwork used for concrete pits. In construction projects, when it’s necessary to pour concrete to create pit-like structures like basement pits, equipment foundation pits, sump pits and so on, this formwork is set up to define the shape and size of the concrete, enabling it to be formed as per the design requirements during the pouring process.

Product Description

|

Type

|

Steel Formwork For Concrete Construction

|

||

|

MOQ

|

500 pcs

|

||

|

Color

|

Regular color is red , other coors are available

|

||

|

Packing

|

1*20ft: about 20tons (regular type steel formwork)

|

||

|

Material

|

Q235 steel

|

||

|

Thickness

|

3mm

|

||

|

Width of Rib

|

55mm

|

||

|

Surface Treatment

|

Painted

|

||

|

Prduction Capacity

|

10 tons per day

|

||

|

Details of Concrete Metal Formwork/Steel Formwork

|

|||

|

1.Concrete metal formwork is made of Q235 steel plate which is heavy/light duty formwork system for concrete wall, beam, slab and column.

|

|||

|

2.There are some ribs in the middle of metal formwork which can strengthen the formwork more steady.

|

|||

|

3.Coined edge can help to form a perfect concrete finish without bubbles.

|

|||

|

4.Metal formwork is spray painted to against rustiness which can be reusable for many times.

|

|||

|

5.Metal formwork is the all-round panel for many construction areas.

|

Application

Flat Form Parameters

Flat Forms – These are used for forming plane surfaces. They are fabricated into rectangular panels of various standard widths and lengths.

|

Code

|

Length(mm)

|

Width(mm)

|

Height(mm)

|

Thickness

|

|

F2018

|

1800

|

200

|

55

|

3

|

|

F2015

|

1500

|

|||

|

F2012

|

1200

|

|||

|

F2007

|

750

|

|||

|

F2006

|

600

|

|||

|

F3018

|

1800

|

300

|

55

|

3

|

|

F3015

|

1500

|

|||

|

F3012

|

1200

|

|||

|

F3007

|

750

|

|||

|

F3006

|

600

|

|||

|

F1518

|

1800

|

150

|

55

|

3

|

|

F1515

|

1500

|

|||

|

F1512

|

1200

|

|||

|

F1509

|

900

|

|||

|

F1506

|

600

|

|||

|

F1218

|

1800

|

125

|

55

|

3

|

|

F1215

|

1500

|

|||

|

F1209

|

900

|

|||

|

F1207

|

750

|

|||

|

F1206

|

600

|

|||

|

F1018

|

1800

|

100

|

55

|

3

|

|

F1015

|

1500

|

|||

|

F1012

|

1200

|

|||

|

F1007

|

750

|

|||

|

F1006

|

600

|

Inner Corner Form Parameters

Inner Corner Forms – These are used for forming inner right-angled corners of a structure

|

Code

|

DIMENSION(MM)

|

|

CF0518

|

100*1800*150

|

|

CF0515

|

100*1500*150

|

|

CF0512

|

100*1500*120

|

|

CF0509

|

100*900*150

|

|

CF0507

|

100*750*150

|

|

CF5518

|

150*1800*150

|

|

CF5515

|

150*1500*150

|

|

CF5512

|

150*1200*150

|

|

CF5507

|

150*750*150

|

|

CF5506

|

150*600*150

|

Corner Angle Form Parameters

Corner Angles – These are used for forming external angles by combining 2 flat forms into a right-angled corner.

|

CODE

|

DIMENSION

|

|

CA0015

|

50*150*50

|

|

CA0012

|

50*1200*50

|

|

CA0009

|

50*900*50

|

|

CA0007

|

50*750*50

|

|

CA0006

|

50*600*50

|

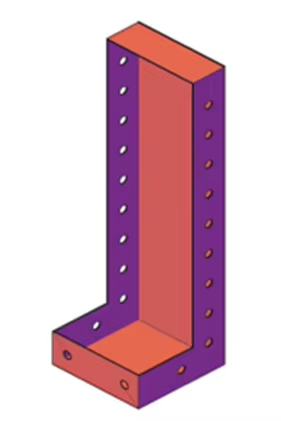

L-Shape Forms Paramaters

L-Shape Forms Paramaters-These are short inner corner forms for forming and short lengths of right-angle corners of structure .They consist of two form faces of various dimensions

|

CODE

|

DIMENSION

|

|

L1015A

|

100*300*150

|

|

L1015B

|

100*350*150

|

|

L1015C

|

100*400*150

|

|

L1015D

|

100*450*150

|

|

L1015E

|

100*500*150

|

|

L1515A

|

150*300*150

|

|

L1515B

|

150*350*150

|

|

L1515C

|

150*400*150

|

|

L1515D

|

150*450*150

|

Square Corner Form

Square Corner Forms – These are used for connecting inner corner forms of L-shaped forms (S-Forms) at the intersection of 3 surfaces

|

CODE

|

DIMENSION

|

|

S1515A

|

150*300*150

|

|

S1515B

|

150*350*150

|

|

S1515C

|

150*400*150

|

|

S1515D

|

150*450*150

|

|

S1515AA

|

100*325*150

|

|

S1515BB

|

100*375*150

|

|

S1515CC

|

100*425*150

|

|

S1515DD

|

100*475*150

|

Packing & Delivery

Tags:

Technical parameter

Scenarios

Scenarios

Scenarios

Scenarios