With the development of the aviation industry and the growth of aviation activities, aircraft have become increasingly larger, heavier, and more complex. Airports have also evolved from simply undeveloped open spaces into comprehensive facilities divided into different functional areas. The areas where aircraft operate on the ground, such as parking aprons, taxiways, and runways, have become increasingly sophisticated. The original dirt roads and grass were no longer sufficient, and paving these surfaces to allow aircraft to operate more effectively became a natural progression.

In the Pacific theater, perforated steel plates, which could be quickly paved with airfield materials, were widely used by the Allies. While unassuming, they effectively ensured the smooth and efficient operation of combat aircraft on the harsh environments of islands, playing a crucial role in the Allies’ victory in gaining air superiority.

The Low-Tech, High-Purpose Marston Mat

In November 1941, a month before the outbreak of the Pacific War, General Arnold, then Vice Chief of Staff of the U.S. Army Air Forces, visited Camp McGar in Marston, North Carolina. There, he observed a large-scale military exercise, but his attention was drawn to the steel plates laid on the runways, prompting him to remark: “This is the greatest achievement of the aviation industry this year!” This steel plate, which received such high praise from the general upon its first application, later became known as the Marston Mat. The Marston Mat is essentially a perforated steel sheet (PSP), often simply referred to as PSP plate; it also has a military designation: M8.

The concept of Marston mats originated in Europe. Before World War II, many military airfields in Britain and France were still unpaved. As aircraft became heavier, wheel brakes were introduced, but the turf at British and French airfields, which was among the best in the world at the time, was barely adequate. With the rise of Germany and the growing tensions in Europe, Britain and France became alarmed. In the event of war, attacks on existing airfields were inevitable, necessitating a large number of temporary airfields. How to quickly construct usable temporary airfields became a key challenge for engineers. British engineers developed rolls of steel mesh for rapid runway installation, while the French developed wooden planks with interlocking mechanisms.

In early 1939, research by Britain and France also attracted the attention of the US Army Air Forces. Analysis revealed that neither of the two proposed solutions was suitable. The British design could not withstand the takeoffs and landings of heavy US bombers and would be difficult to repair after damage, while the French design was too heavy and inconvenient to install. Therefore, Carnegie Steel Company in Illinois, based on the requirements of the US Army Air Forces and incorporating the experience of Britain and France, ultimately developed the Marston pad.

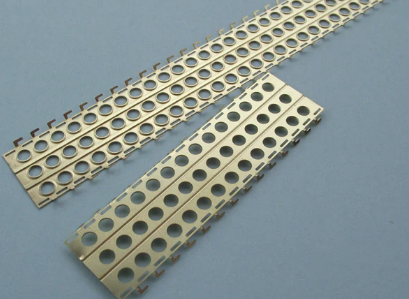

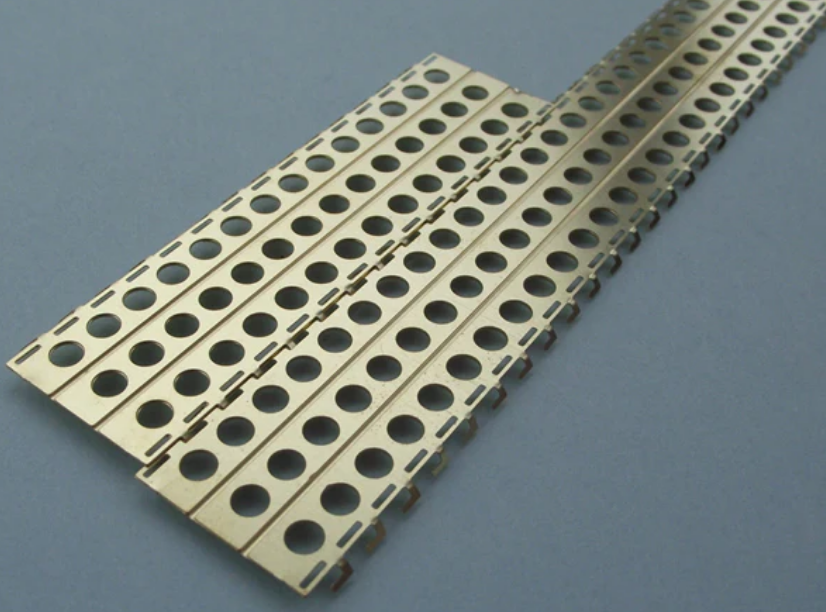

The M8 Marston pad, widely used during World War II, was made of stamped steel sheet. Each sheet was 3 meters long, 0.38 meters wide, and weighed 30 kilograms. Two horizontal grooves divided each sheet into three sections, and a total of 87 holes were punched in it. There were clips at the front and back for splicing the sheets together.

The Marston mat is easy and quick to install; it can be installed on a simply leveled surface. The mats are laid in an alternating pattern to widen the track. During installation, as needed, a certain number of mats can be reinforced by using U-shaped clips to drive them into the ground, or by welding. For a more sophisticated setup, a layer of straw mats or similar material can be laid as a base first.

Marston mats were widely used during World War II due to their simple and quick installation and easy repair and replacement, appearing in theaters from the Pacific to Europe and Africa. Without them, Allied air power could not be deployed forward in a timely manner, its operational efficiency would be greatly reduced, and it could even have a significant impact on the course of the war.

Since Marston mats are so useful, why didn’t the Axis powers use them? Yes, Japan did. They researched similar runway mats in 1942 and used them in Rabaul. However, while the technology wasn’t advanced, it was resource-intensive and demanding. During World War II, the United States produced approximately 2 million tons of M8 Marston mats and, with its superior logistical capabilities, transported them to the battlefields where they were needed, laying them out at will. The Axis powers, however, were unable to do so.

Post-war Applications and Development: After World War II, numerous Marston mats were left behind on various battlefields, and local residents made full use of them. They were used in sidewalks, fences, pigsties, doors, windows, etc.—nothing was wasted if it could be used.

Marston pads continued to play a role in the Berlin Airlift of 1948, and later in the Korean War, Vietnam War, and Afghanistan. By this time, Marston pads had evolved, adopting a design without holes or with small holes to accommodate the jet aircraft’s aversion to splashes.

During the Vietnam War, due to the further increase in the weight of fighter jets, Marston mats were relegated to a secondary role and were mainly used for laying propeller plane runways and helipads.

While the M8 Marston pad was widely used, a small quantity of the aluminum M9 Marston pad was also produced. The M9 was lighter, weighing approximately 20 kilograms. However, aluminum was a strategic material during World War II and had a shorter lifespan than steel, so the M9 was not widely adopted. After the war, various new Marston pad materials were developed to meet the requirements of larger and heavier aircraft takeoffs and landings.

The new Marston mats are no longer limited to rectangular or square shapes; polygonal Marston mats are also appearing. Their applications extend beyond quickly laying aircraft runways; they are used for various platforms and ground surfaces, and even in disaster relief. Common everyday products such as interlocking balcony flooring, bathroom anti-slip mats, and wall-mounted pegboards are also considered derivatives of this technology.

That concludes the article. Thank you for reading.

Marston Mat Ww2 For Sale

Company Telephone:+8615888703908 Or +8602287336612

E-mail Address:jane@tjtsxgroupe.com

Company Location:Room 1501, Block A, North Tower, Wisdom Mountain, No. 1 Gonghua Road, Huayuan Industrial Park, Xiqing District, Tianjin, China.